News Center

Recommending Products

Contact: Mr. Jin

Tel: 13901575780

0512-52428686

Contact: Mr. Zha

Tel: 13913639797

0512-52422071

Address: No. 59, Huyi Road, Liantang, Shanghu Town, Changshu City, Jiangsu Province.

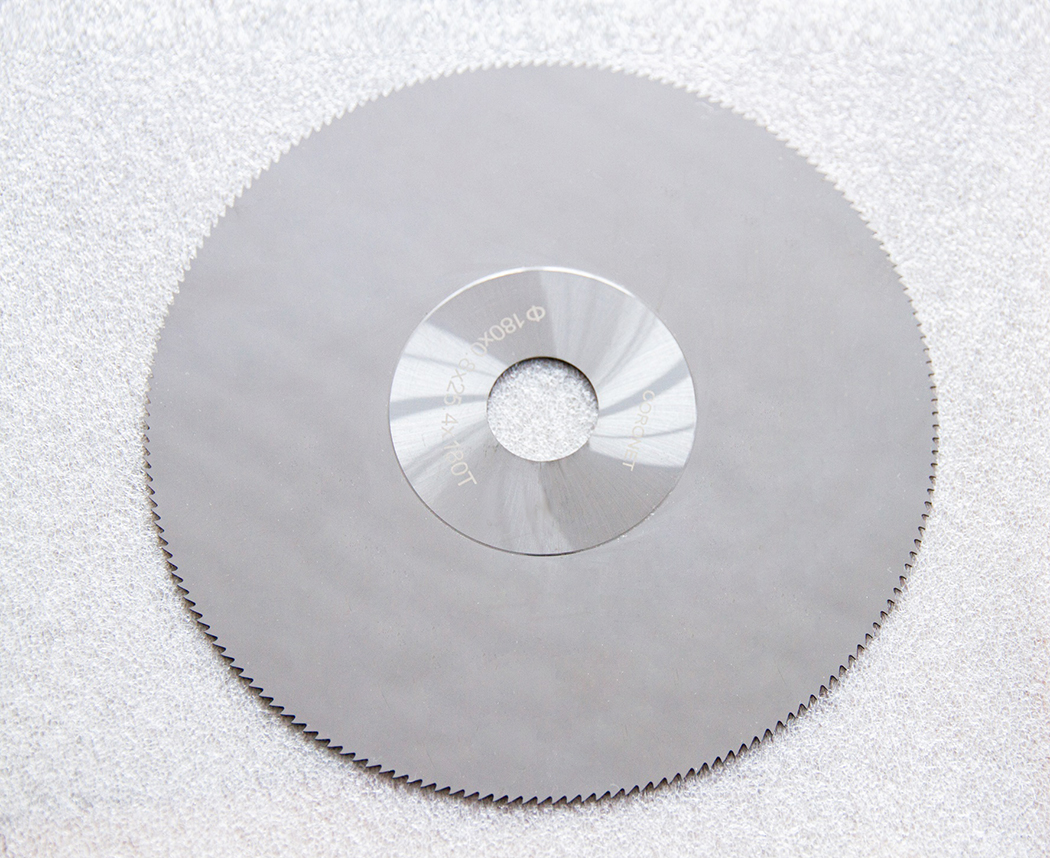

What are the applications of tungsten steel pipe cutting saw blades in the metal processing industry

Tungsten steel pipe cutting saw blades are widely used in the metal processing industry due to their high hardness, high wear resistance, and good cutting performance. The following are some main aspects:Sources:wjfilm.cn | PublishDate:2025.03.04

1. Pipe cutting

Stainless steel pipe cutting: In fields such as building decoration, machinery manufacturing, and chemical engineering, it is often necessary to cut and process stainless steel pipes. The tungsten steel pipe cutting saw blade can easily cut stainless steel pipes of different specifications and wall thicknesses, with a smooth cutting surface and high precision. It can effectively reduce burrs and deformation, improve processing quality and efficiency.

Carbon steel pipe cutting: Carbon steel pipes are widely used in industries such as petroleum, natural gas, and construction. The tungsten steel cutting saw blade can quickly and accurately cut carbon steel pipes, suitable for cutting large-diameter and thick walled carbon steel pipes. It can withstand high cutting forces, ensuring the stability and reliability of the cutting process.

Alloy steel pipe cutting: Due to the presence of multiple alloy elements and high hardness, alloy steel pipes are difficult to cut. The tungsten steel cutting saw blade, with its excellent wear resistance and sharpness, can efficiently cut alloy steel pipes, meeting the precision requirements for alloy steel pipe processing in fields such as aerospace and automotive manufacturing.

2. Profile cutting

Angle steel cutting: Angle steel is a commonly used profile in the manufacturing of building structures, mechanical frames, and other materials. The tungsten steel pipe cutting saw blade can cut angle steel at right or oblique angles with high cutting accuracy, ensuring the dimensional and angular accuracy of the angle steel, and providing a good foundation for subsequent assembly and welding work.

Channel steel cutting: Channel steel is widely used in construction, bridge and other engineering projects. The tungsten steel pipe cutting saw blade can cut channel steel of different lengths and angles according to engineering requirements. During the cutting process, the saw blade has good stability and is not prone to deviation and shaking, ensuring cutting quality.

I-beam cutting: In large buildings and steel structure engineering, I-beams are the main load-bearing components. The tungsten steel pipe cutting saw blade can efficiently cut I-beams, even large-sized I-beams can be cut with suitable tungsten steel saw blades, meeting the material processing needs in engineering construction.

3. Component processing

Gear blank cutting: In the process of gear manufacturing, it is necessary to cut metal materials into gear blanks. The tungsten steel cutting saw blade can correctly cut gear blanks, ensuring the dimensional accuracy and surface quality of the blanks, and providing a good foundation for subsequent gear processing procedures.

Cutting of shaft parts: Shaft parts are key components in mechanical transmission, and during the machining process, it is necessary to cut the shaft material. The tungsten steel pipe cutting saw blade can correctly cut the shaft material, with high perpendicularity and flatness between the cutting surface and the axis, which is conducive to improving the machining accuracy and assembly quality of shaft parts.

Flange cutting: Flanges are commonly used connectors in pipeline connections and equipment installation. The tungsten steel pipe cutting saw blade can cut and process the flange blank, ensuring the dimensional accuracy of the outer diameter, inner diameter, and thickness of the flange, as well as the flatness of the cutting surface, ensuring the sealing performance and connection strength of the flange.